Manufacturing Execution System

Our modular turnkey IT system for the beverage industry

The demands made of today’s beverage industry are many and varied. Production lines thus have to be effectively controlled and run at optimum capacity. Digitalization offers enormous potential in the attempt to achieve this. As part of our range of digital services, we offer Manufacturing Execution System (MES) systems and solutions that can be perfectly integrated into your infrastructure. Our Innoline Flex Control (IFC) and Innoline Basic Line Monitoring (BLM) products are modular software packages which have been adapted especially for the beverage industry. They ensure transparency and greater efficiency throughout the entire beverage filling process, giving you an essential competitive edge on ever narrower markets.

The perfect symbiosis of all modules helps you to significantly increase your overall equipment effectiveness and clearly reduce your system downtime. With us, you can react quickly to new market demands and improve all of your filling and packaging processes.

Innoline Flex Control (IFC) is scalable for both individual filling lines and entire plants and can be included in new and existing systems, regardless of the manufacturer. The system is based on a central database for all functions of the modules listed in the following:

- Line monitoring: this module acquires production data from filling, packaging and filling-related processes and evaluates this information using defined performance indicator models.

- Order execution: the order execution module is an order management system for filling and packaging lines that allows you to allocate production data to filling orders and filling batches. With this function, the collected data and computed KPIs can now also be assigned to items (SKU) and orders. Orders can be transferred from an ERP system. All prepared, current, interrupted and concluded orders are available at a glance.

- Order material tracking: the order material tracking module enables batch tracking with allocation of production batches to filling orders, filling batches and pallets. Transfer orders for automated transport systems (such as LGVs) can also be realized as an option. Consumption postings can be generated based on material movements and reported to the ERP system.

- Order scheduling: the order scheduling module ensures optimum capacity utilization and adherence to deadlines. The graphic planning board with an online display of order statuses and machine states helps you to optimize your filling planning process. Machine utilization can be either automatic or manual. This means that you can react very quickly to short-term customer inquiries and at the same time optimize your order sequence.

Your benefits with Innoline Flex Control

- Plan orders constructively and reduce downtime

- Generation of transport missions for automatic material supply

- Detect articles with high consumption

- Avoid loss of quality through data specification on coding and inspection systems

- Horizontal and vertical interfaces to your IT systems

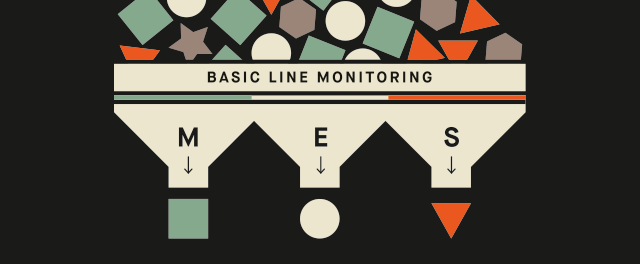

Do you want to concentrate on assessing your line efficiency and only record the data points relevant to the calculation of performance indicators and analysis of weak points? Our BLM software works like its ‘big sister’ IFC yet focuses solely on process data, product and consumption meters and determining the cause of any external disruptions. This only gives your employees the information they actually need to identify weak points or reasons for loss in performance, allowing them to react immediately. The Basic Line Monitoring module has a web client for even greater convenience and can thus also be retrieved on a smartphone or tablet.

Your benefits with Basic Line Monitoring

- Greater line monitoring transparency

- Convenient, intuitive and simple operation through a web client or, optionally, directly on the machine

- Users are only given the information they need to perform their tasks

- Data can also be retrieved on mobile devices

- Generation of standard reports without advance manual filtering